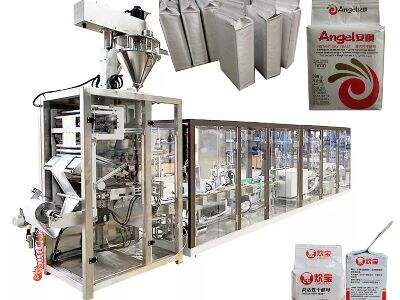

There following types of packaging machines are available based on product types. Powder packaging machines and granule packaging machines are two types of machines. Although they may sound similar, they have significant differences. Understanding these differences will allow you to accurately choose the correct machine for your product.

Machines for Powder or Granule Packaging:

Powder packaging machines serve to pack fine powders such as flour, spices, or powdered drinks. These powder packaging machine got special booster features to prevent the powder clogging in the passage of the machine, ensuring it measures and heat seals properly. Granule packaging machines are used for larger items such as beans, nuts, or cereal. These machines have components that can accommodate the granules’ greater size and keep them sealed in the package.

That Are There on Every Machine:

A powder packaging machine has a more delicate measuring system than others to ensure powder is measured correctly. They also contain components that prevent the powder from adhering to the machine, clogging it. Granule packing machines have larger weighing systems for the larger granules. These powder packaging come fitted with components capable of handling the heftier cuts and keeping them crop-tight.

Differences in Use and the Packaging Process:

The use of a powder packaging machine or a granule packaging machine is determined by the type of product. Fine powders require precision measurements and sealing, so they work better with powder packaging machines. Granule packaging machines are designed for bulk items that require good sealing. The milk powder packaging machine of this product are also specially packaged according to the type of machine.

Picking the Right Machines for Increasing the Productivity

Choosing the right machine is essential when it comes to fitting your product and streamlining the packaging process. Selecting the right machine to properly measure, seal, and package your powder or granule product will ensure seamless operation. It will enhance the quality of your product and assist you in saving time and resources.

EN

EN